How to use the pure electric multi-function high-pressure washing car, the editor specially compiled the instructions for the pure electric multi-functional high-pressure washing car, instructing the user to operate the high-pressure washing car, so that the user can get started faster and provide written instructions. Here are the specific details:

1. Specification model: BY-C7-L

2, the scope of application: ground dust, stains, sanitation stations, bus stations, engineering vehicle cleaning and road sprinkling maintenance, is an ideal high-pressure cleaning equipment for urban cleaning, sanitation, construction, industrial and mining enterprises.

3. Features: safety, power saving, energy saving, environmental protection, easy to use, light weight, high pressure and adjustable pressure, etc.

Fourth, the basic characteristics:

◆Chassis: Zongshen heavy duty electric tricycle chassis is used, but there are no special accessories. The accessories are universally compatible and easy to maintain. The frame adopts an integrated curved beam structure, with mechanical high and low gear speed regulation, equipped with oversized tires and shock absorbers, which can easily cope with high load conditions.

◆Box body: The box body adopts the sheet metal spraying process, which must be sprayed as a whole after pickling and phosphating. It has a built-in rotomolding water tank with a volume of 700 liters. The water tank has its own special interface for cleaning and sewage, and the side of the box has its own water level observation window, which is convenient for real-time observation of the water level.

◆Cleaning pump unit: 60V DC frequency conversion brushless high-pressure washing machine.

◆Barrel accessories: Equipped with a hand-held high-pressure water gun, a 15-meter high-pressure water pipe, and an automatic rewinding and unwinding reel, which is convenient for retracting and unwinding the high-pressure pipe.

◆Vehicle size: (length * width * height) 3300 * 1000 * 1600 (mm), small body, agile shuttle various streets.

5. Detailed explanation of main structure and function:

1. Side flushing nozzle, double valve control, the flushing direction can be changed at any time according to the needs of different grounds, the water direction can be adjusted arbitrarily during use, and the front, back, up, down, left, and right rotations can be rotated 360°.

2. Hydraulic valve combination, using three-way and straight-through matching methods, can control the front flush, side flush, and hand-held spray gun. Centralized control is easy to use.

3. Sewage outlet. When the vehicle is not used for a long time, the water in the water tank needs to be released. After a period of use, there is too much dirt in the water tank. When cleaning the water tank, use the water outlet to clean the dirt in the water tank. The water tank overflow port, after the water tank is filled with water, there is an overflow from this port。

4. Water level observation port

5. Hose reel, 15 meters long hose reel, can be stretched and rolled at will according to the distance during work, which is more convenient.

6. Fire water injection port

7. 60V DC frequency conversion high pressure cleaning machine

8. Filter to prevent small impurities from entering the pipeline to block the nozzle.

9. High pressure pump system

10. Hand-held high-pressure spray gun, quick-plug connector, can change nozzles of various angles at any time

11. Warning light device

12. LED headlights, turn signals, warning horns

14. Function button indication

7. Quick installation and operation guide for the high-voltage generator part:

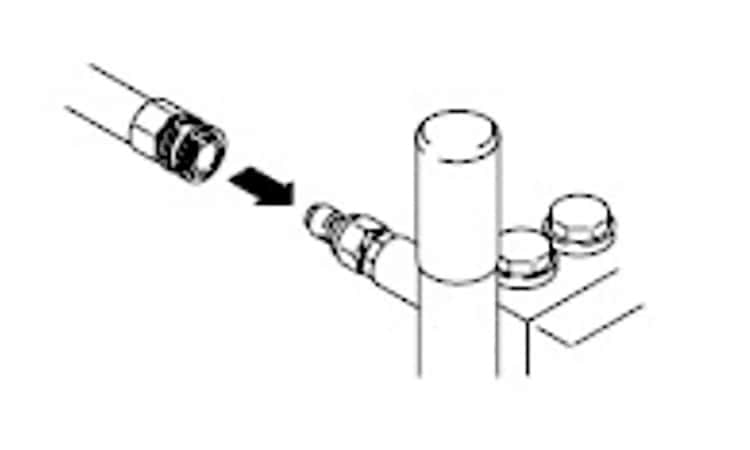

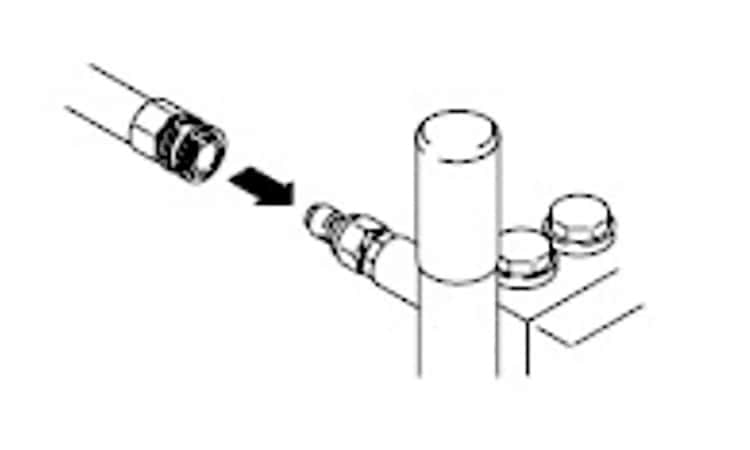

1. Connect the high-pressure hose and the high-pressure gun

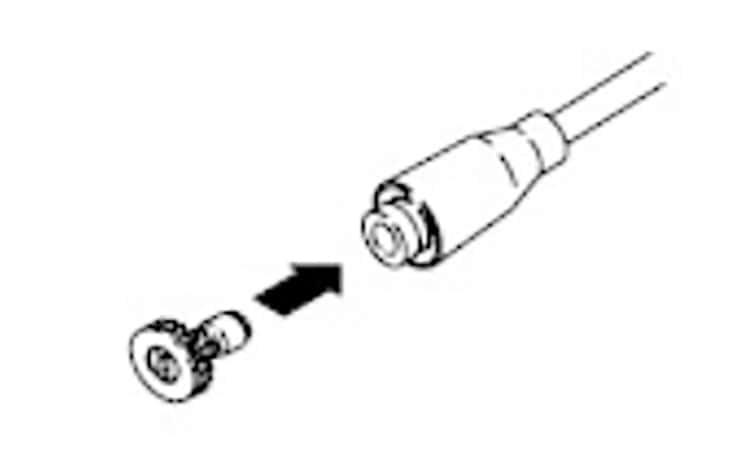

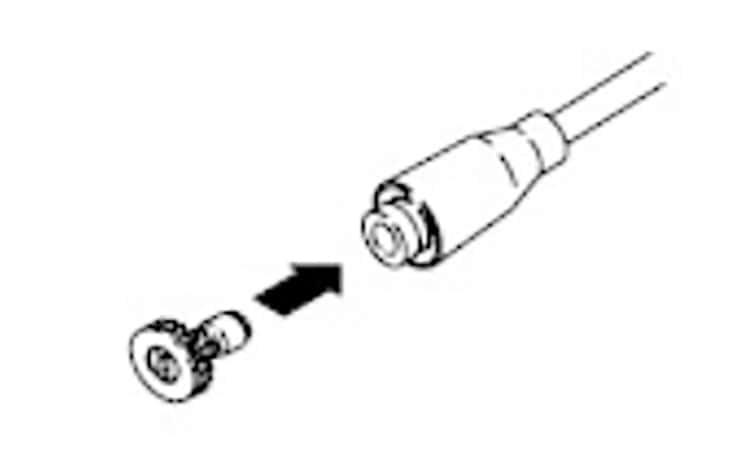

2. Install high pressure nozzle

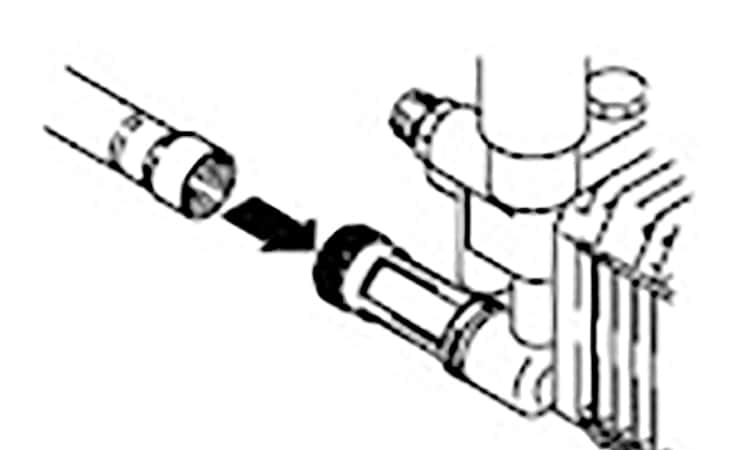

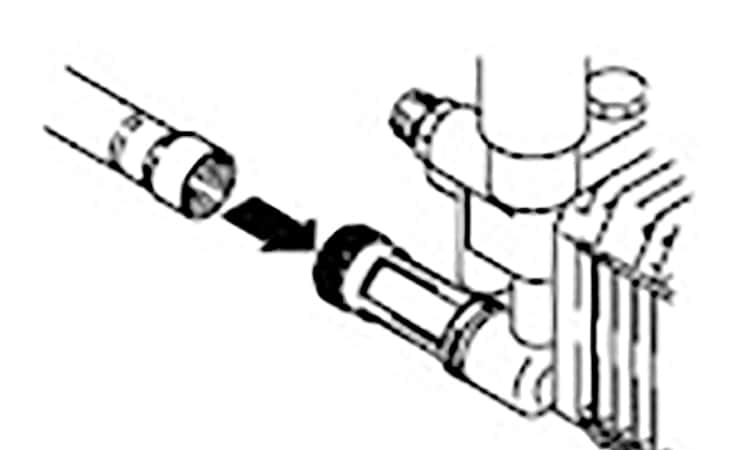

3. Connect the water inlet pipe

Use a hard water pipe with an inner diameter greater than 3/4" (19 mm) to connect the faucet to the water inlet of the high pressure washer. The length of the water inlet pipe should not exceed 15 meters. If the water is self-primed through the water tank, the water level of the water tank should not be lower than 1.5 meters from the water inlet. , and it is recommended to use a steel wire pipe with anti-deformation function as the water inlet pipe.

Note: It is forbidden to start the machine in the state of no water connection!

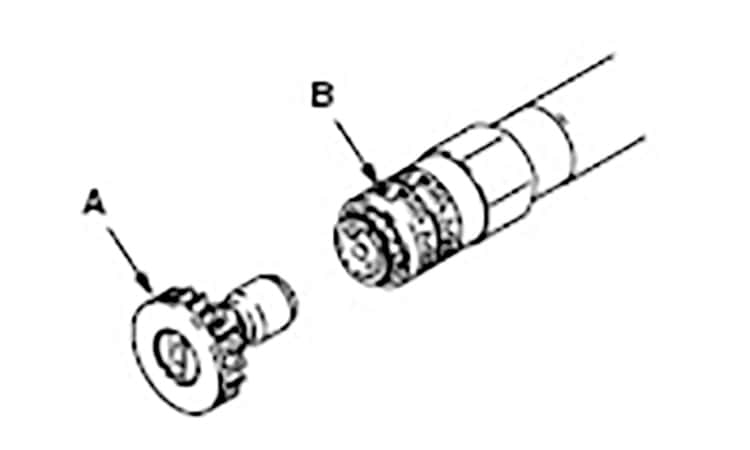

4. Install and replace the nozzle

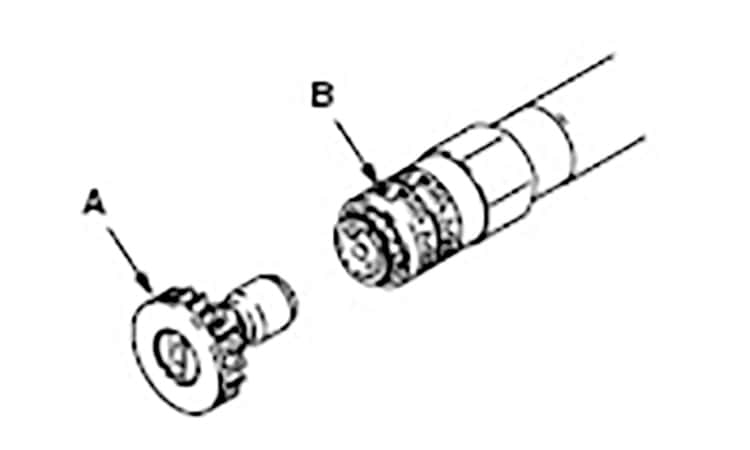

Push back the adapter ring (B) of the quick-connect joint, pull out the original nozzle (A) after the adapter ring is released, insert a new nozzle, and push the adapter ring forward again to lock the nozzle.

Precautions: The red nozzle is a 0-degree direct injection nozzle, which will cause serious damage to the surface of people and objects. It is strictly forbidden to use the red nozzle directly on the body of people and livestock during operation!

Eight, common problems and troubleshooting

1. Low pressure:

2. Water leakage:

Note: If the equipment has water leakage, oil leakage, no pressure, etc., please contact our company in time.

Nine, product maintenance and maintenance matters:

1. When using the high-pressure pump for the first time, connect the water inlet of the cleaning machine with the tap, and pre-inject clean water into the pump until the water overflows at the water outlet to prevent the high-pressure plunger from dry grinding (consequences: dry grinding for more than 20 seconds may cause the high-pressure pump gaskets are scrapped).

2. It is strictly forbidden to let the machine idle for more than three minutes when the gun handle is closed. When idling, the high-pressure pump plunger still compresses the water stored in the pump (about 20 ml) at a high speed, so that the water temperature rises sharply, making the plunger water seal, oil seal, etc. The rubber seals are rapidly degenerated and aged, which affects their service life (solution: when it is inconvenient to turn off/start frequently during operation, you can open the gun handle every two minutes during the gun stop interval, drain the hot water in the pump, and let new cold water refill the pump).

3. The pressure in the gun must be released after the shutdown. The high pressure in the gun means that the pump body and the external gun and pipe system are continuously in a high pressure state, which affects the service life of the high-pressure seal.

4. Regularly (every week) check the water inlet filter to prevent the clogging of insects, leaves, paper, hair and other foreign objects and the air tightness of the water inlet pipe to prevent air from entering (any link from the water tank to the water inlet pipe section of the pump body is airtight If it is not strict (there is no drip leakage), it will cause gas inhalation under the self-priming negative pressure of the pump body), these two situations are the most likely scenarios to reduce the water jet pressure.

5. Winter maintenance:

(1) Use low-temperature antifreeze oil (10W-30) when the cleaning machine is used in winter.

(2) Before the washing machine is put into storage, disconnect the water supply, run it for 2 seconds, and discharge the accumulated water in the pump (do not need to be exhausted) to prevent the water body from freezing and expanding, and damaging the pump body and the plunger seal.

6. The filter must be checked before use in each shift to see if there are too many impurities and cleaned up.

7. The water tank must be checked regularly and kept clean. If there are impurities at the bottom, the sewage outlet should be opened to remove them.

8. When walking in a non-working state, the electric lifting device must be raised, and the switch must be turned to the "stop" state after raising to avoid collision.

10. Warm reminder

1. Machine lubrication

Good lubrication of equipment is an old and new problem. The plunger, bearing, swash plate and crank of the high-pressure pump of the cleaning machine need good lubrication and heat dissipation during movement. scrapped inside. When using the high-pressure cleaner, you must pay attention to: A. Check the stock of lubricating oil every shift (no more or less); B. Replace the new lubricating oil every three months (the first time you use 50 jobs, and then every 300 -500 working hours).

2. The importance of water sources

The pump head of high-pressure flushing mainly relies on water to lubricate and cool. If the water intake is insufficient, it will cause poor cooling and lubrication, insufficient pressure, and long-term operation may cause the equipment to be scrapped. Therefore, we should pay attention to the sufficient water intake when using the high pressure washer. At the same time, pay attention to the cleanliness of the water source. If it is not clean, add a filter to ensure the cleanliness of the water source.

3. We often encounter high-pressure water leakage when using high-pressure washing machines. The leakage of the high-pressure pump can easily cause the motor to heat up and accelerate the damage to the seals and other components. Therefore, the cause of the leakage should be found out in time to solve the leakage.

4. Cleaning of the filter screen of the equipment itself If the water inlet filter screen of the equipment is not cleaned in time, it will cause insufficient pressure and foreign objects will enter the pump head, so check the cleanliness of the water inlet filter screen before use, if there are too many foreign objects or impurities , the filter needs to be cleaned. Cleaning of the gasoline filter, the blockage of the gasoline filter will cause damage to the oil pump and fuel injector, so it should be cleaned every week.

11. Operation steps

(1) Operation steps of high pressure water gun

1. Open the water valve at the front of the water filter to provide sufficient water source for the high-pressure pump

2. Turn on the switch of the high-pressure water nozzle to ensure that the high-pressure water flows out smoothly (open the three-way valve in the middle of the handlebar, the middle position is the side flushing, and turning to the right is the hand-held high-pressure opening)

3. Back flushing use: insert the back flushing high pressure pipe into the water outlet of the hose reel

4. Start the cleaning machine:

(1) Turn on the power switch of the washing machine

(2) Gently rotate the rotary switch to slowly increase the motor speed

5. The pressure of the high-pressure pump has been debugged before leaving the factory, and there is no need to adjust it during use.

6. Stop:

(1) When stopping, first turn the rotary switch to the lowest speed

(2) Turn off the power of the washing machine

Note: After the shutdown, it must be ensured that there is no pressure in the pipeline. Method: After shutdown, open the valve high-pressure valve to release the pressure, and open the high-pressure spray gun to release the pressure.

(2) Spray operating device

1. Open the water valve at the front of the water filter to provide sufficient water source for the high-pressure pump

2. Insert the water inlet high pressure pipe of the spray rod into the outlet of the washing machine, and insert the spray rod into the spray device

3. Open the gear lever and put it in the designated position (if it encounters an obstacle, it can be automatically returned)

4. Start the cleaning machine:

(1) Turn on the power switch of the washing machine

(2) Gently rotate the rotary switch to slowly increase the motor speed

5. Stop:

(1) When stopping, first turn the rotary switch to the lowest speed

(2) Turn off the power of the washing machine

Note: The pressure of the washing machine should not be too large, as long as the spray effect is achieved.

12. Precautions for product maintenance and use

1. It is strictly forbidden to start the machine for more than three minutes when the gun handle is closed. When idling, the high-pressure pump plunger still compresses the water stored in the pump (about 20 ml) at a high speed, so that the water temperature rises sharply, making the plunger water seal, oil seal and other rubber seals The parts are rapidly degenerated and aged, which will affect their service life (solution: when it is inconvenient to turn off/start frequently during the operation, you can open the gun handle every two minutes during the gun stop interval, drain the hot water in the pump, and let new cold water refill pump body)

2. The pressure in the gun must be released after the shutdown. The high pressure in the gun means that the pump body and the external gun and pipe system are continuously in a high pressure state, which affects the service life of the high-pressure seal;

3. Check the water inlet filter regularly (every week) to prevent clogging by foreign objects such as insects, leaves, paper, hair, etc. and the air tightness of the water inlet pipe to prevent air from entering (air tightness in any link of the water inlet pipe section from the water tank to the pump body Not strict (no drip leakage occurs), gas will be inhaled under the self-priming negative pressure of the pump body), these two situations are the most likely scenarios to reduce the water jet pressure;

4. The filter must be checked before use in each shift to see if there are too many impurities and cleaned up;

5. The water tank must be checked regularly and kept clean. If there are impurities at the bottom, the sewage outlet should be opened to remove them;

6. When walking in a non-working state, the electric lifting device must be raised, and the switch must be turned to the "stop" state after raising to avoid collision;

7. Important: Turn off the power switch when the washing machine is not in use

8. It is strictly forbidden for the water tank to be short of water to avoid idling of the high-pressure pump.

13. Maintenance Instructions

1. The model used by the pump is 4-stroke motorcycle oil SAE15W/40.

2. After the new machine is used for 20 hours, the crankshaft of the pump must be cleaned. The specific method is as follows: remove the oil drain screw to drain the oil in the crankcase, re-install the oil drain screw, and then add clean kerosene to the crankshaft. After 10-15 seconds, turn off the equipment, drain the kerosene completely, and inject new oil.

3. After the accumulative use reaches 100 hours, change the oil in the same way, and then change the oil every 100 hours, which is very important to prolong the service life of the pump.

4. Winter maintenance:

(1) Use low temperature antifreeze oil (10W-30) when using in winter;

(2) Disconnect the water supply before entering the warehouse, run it for 2 seconds, and discharge the accumulated water in the pump (do not need to be exhausted) to prevent the water body from freezing, expanding, and damaging the pump body and plunger seals;

Note: Please carry out maintenance in strict accordance with the requirements. The manufacturer will not provide warranty for failures caused by untimely maintenance.

How to use the pure electric multi-function high-pressure washing car, the editor specially compiled the instructions for the pure electric multi-functional high-pressure washing car, instructing the user to operate the high-pressure washing car, so that the user can get started faster and provide written instructions. Here are the specific details:

1. Specification model: BY-C7-L

2, the scope of application: ground dust, stains, sanitation stations, bus stations, engineering vehicle cleaning and road sprinkling maintenance, is an ideal high-pressure cleaning equipment for urban cleaning, sanitation, construction, industrial and mining enterprises.

3. Features: safety, power saving, energy saving, environmental protection, easy to use, light weight, high pressure and adjustable pressure, etc.

Fourth, the basic characteristics:

◆Chassis: Zongshen heavy duty electric tricycle chassis is used, but there are no special accessories. The accessories are universally compatible and easy to maintain. The frame adopts an integrated curved beam structure, with mechanical high and low gear speed regulation, equipped with oversized tires and shock absorbers, which can easily cope with high load conditions.

◆Box body: The box body adopts the sheet metal spraying process, which must be sprayed as a whole after pickling and phosphating. It has a built-in rotomolding water tank with a volume of 700 liters. The water tank has its own special interface for cleaning and sewage, and the side of the box has its own water level observation window, which is convenient for real-time observation of the water level.

◆Cleaning pump unit: 60V DC frequency conversion brushless high-pressure washing machine.

◆Barrel accessories: Equipped with a hand-held high-pressure water gun, a 15-meter high-pressure water pipe, and an automatic rewinding and unwinding reel, which is convenient for retracting and unwinding the high-pressure pipe.

◆Vehicle size: (length * width * height) 3300 * 1000 * 1600 (mm), small body, agile shuttle various streets.

5. Detailed explanation of main structure and function:

1. Side flushing nozzle, double valve control, the flushing direction can be changed at any time according to the needs of different grounds, the water direction can be adjusted arbitrarily during use, and the front, back, up, down, left, and right rotations can be rotated 360°.

2. Hydraulic valve combination, using three-way and straight-through matching methods, can control the front flush, side flush, and hand-held spray gun. Centralized control is easy to use.

3. Sewage outlet. When the vehicle is not used for a long time, the water in the water tank needs to be released. After a period of use, there is too much dirt in the water tank. When cleaning the water tank, use the water outlet to clean the dirt in the water tank. The water tank overflow port, after the water tank is filled with water, there is an overflow from this port。

4. Water level observation port

5. Hose reel, 15 meters long hose reel, can be stretched and rolled at will according to the distance during work, which is more convenient.

6. Fire water injection port

7. 60V DC frequency conversion high pressure cleaning machine

8. Filter to prevent small impurities from entering the pipeline to block the nozzle.

9. High pressure pump system

10. Hand-held high-pressure spray gun, quick-plug connector, can change nozzles of various angles at any time

11. Warning light device

12. LED headlights, turn signals, warning horns

14. Function button indication

7. Quick installation and operation guide for the high-voltage generator part:

1. Connect the high-pressure hose and the high-pressure gun

2. Install high pressure nozzle

3. Connect the water inlet pipe

Use a hard water pipe with an inner diameter greater than 3/4" (19 mm) to connect the faucet to the water inlet of the high pressure washer. The length of the water inlet pipe should not exceed 15 meters. If the water is self-primed through the water tank, the water level of the water tank should not be lower than 1.5 meters from the water inlet. , and it is recommended to use a steel wire pipe with anti-deformation function as the water inlet pipe.

Note: It is forbidden to start the machine in the state of no water connection!

4. Install and replace the nozzle

Push back the adapter ring (B) of the quick-connect joint, pull out the original nozzle (A) after the adapter ring is released, insert a new nozzle, and push the adapter ring forward again to lock the nozzle.

Precautions: The red nozzle is a 0-degree direct injection nozzle, which will cause serious damage to the surface of people and objects. It is strictly forbidden to use the red nozzle directly on the body of people and livestock during operation!

Eight, common problems and troubleshooting

1. Low pressure:

2. Water leakage:

Note: If the equipment has water leakage, oil leakage, no pressure, etc., please contact our company in time.

Nine, product maintenance and maintenance matters:

1. When using the high-pressure pump for the first time, connect the water inlet of the cleaning machine with the tap, and pre-inject clean water into the pump until the water overflows at the water outlet to prevent the high-pressure plunger from dry grinding (consequences: dry grinding for more than 20 seconds may cause the high-pressure pump gaskets are scrapped).

2. It is strictly forbidden to let the machine idle for more than three minutes when the gun handle is closed. When idling, the high-pressure pump plunger still compresses the water stored in the pump (about 20 ml) at a high speed, so that the water temperature rises sharply, making the plunger water seal, oil seal, etc. The rubber seals are rapidly degenerated and aged, which affects their service life (solution: when it is inconvenient to turn off/start frequently during operation, you can open the gun handle every two minutes during the gun stop interval, drain the hot water in the pump, and let new cold water refill the pump).

3. The pressure in the gun must be released after the shutdown. The high pressure in the gun means that the pump body and the external gun and pipe system are continuously in a high pressure state, which affects the service life of the high-pressure seal.

4. Regularly (every week) check the water inlet filter to prevent the clogging of insects, leaves, paper, hair and other foreign objects and the air tightness of the water inlet pipe to prevent air from entering (any link from the water tank to the water inlet pipe section of the pump body is airtight If it is not strict (there is no drip leakage), it will cause gas inhalation under the self-priming negative pressure of the pump body), these two situations are the most likely scenarios to reduce the water jet pressure.

5. Winter maintenance:

(1) Use low-temperature antifreeze oil (10W-30) when the cleaning machine is used in winter.

(2) Before the washing machine is put into storage, disconnect the water supply, run it for 2 seconds, and discharge the accumulated water in the pump (do not need to be exhausted) to prevent the water body from freezing and expanding, and damaging the pump body and the plunger seal.

6. The filter must be checked before use in each shift to see if there are too many impurities and cleaned up.

7. The water tank must be checked regularly and kept clean. If there are impurities at the bottom, the sewage outlet should be opened to remove them.

8. When walking in a non-working state, the electric lifting device must be raised, and the switch must be turned to the "stop" state after raising to avoid collision.

10. Warm reminder

1. Machine lubrication

Good lubrication of equipment is an old and new problem. The plunger, bearing, swash plate and crank of the high-pressure pump of the cleaning machine need good lubrication and heat dissipation during movement. scrapped inside. When using the high-pressure cleaner, you must pay attention to: A. Check the stock of lubricating oil every shift (no more or less); B. Replace the new lubricating oil every three months (the first time you use 50 jobs, and then every 300 -500 working hours).

2. The importance of water sources

The pump head of high-pressure flushing mainly relies on water to lubricate and cool. If the water intake is insufficient, it will cause poor cooling and lubrication, insufficient pressure, and long-term operation may cause the equipment to be scrapped. Therefore, we should pay attention to the sufficient water intake when using the high pressure washer. At the same time, pay attention to the cleanliness of the water source. If it is not clean, add a filter to ensure the cleanliness of the water source.

3. We often encounter high-pressure water leakage when using high-pressure washing machines. The leakage of the high-pressure pump can easily cause the motor to heat up and accelerate the damage to the seals and other components. Therefore, the cause of the leakage should be found out in time to solve the leakage.

4. Cleaning of the filter screen of the equipment itself If the water inlet filter screen of the equipment is not cleaned in time, it will cause insufficient pressure and foreign objects will enter the pump head, so check the cleanliness of the water inlet filter screen before use, if there are too many foreign objects or impurities , the filter needs to be cleaned. Cleaning of the gasoline filter, the blockage of the gasoline filter will cause damage to the oil pump and fuel injector, so it should be cleaned every week.

11. Operation steps

(1) Operation steps of high pressure water gun

1. Open the water valve at the front of the water filter to provide sufficient water source for the high-pressure pump

2. Turn on the switch of the high-pressure water nozzle to ensure that the high-pressure water flows out smoothly (open the three-way valve in the middle of the handlebar, the middle position is the side flushing, and turning to the right is the hand-held high-pressure opening)

3. Back flushing use: insert the back flushing high pressure pipe into the water outlet of the hose reel

4. Start the cleaning machine:

(1) Turn on the power switch of the washing machine

(2) Gently rotate the rotary switch to slowly increase the motor speed

5. The pressure of the high-pressure pump has been debugged before leaving the factory, and there is no need to adjust it during use.

6. Stop:

(1) When stopping, first turn the rotary switch to the lowest speed

(2) Turn off the power of the washing machine

Note: After the shutdown, it must be ensured that there is no pressure in the pipeline. Method: After shutdown, open the valve high-pressure valve to release the pressure, and open the high-pressure spray gun to release the pressure.

(2) Spray operating device

1. Open the water valve at the front of the water filter to provide sufficient water source for the high-pressure pump

2. Insert the water inlet high pressure pipe of the spray rod into the outlet of the washing machine, and insert the spray rod into the spray device

3. Open the gear lever and put it in the designated position (if it encounters an obstacle, it can be automatically returned)

4. Start the cleaning machine:

(1) Turn on the power switch of the washing machine

(2) Gently rotate the rotary switch to slowly increase the motor speed

5. Stop:

(1) When stopping, first turn the rotary switch to the lowest speed

(2) Turn off the power of the washing machine

Note: The pressure of the washing machine should not be too large, as long as the spray effect is achieved.

12. Precautions for product maintenance and use

1. It is strictly forbidden to start the machine for more than three minutes when the gun handle is closed. When idling, the high-pressure pump plunger still compresses the water stored in the pump (about 20 ml) at a high speed, so that the water temperature rises sharply, making the plunger water seal, oil seal and other rubber seals The parts are rapidly degenerated and aged, which will affect their service life (solution: when it is inconvenient to turn off/start frequently during the operation, you can open the gun handle every two minutes during the gun stop interval, drain the hot water in the pump, and let new cold water refill pump body)

2. The pressure in the gun must be released after the shutdown. The high pressure in the gun means that the pump body and the external gun and pipe system are continuously in a high pressure state, which affects the service life of the high-pressure seal;

3. Check the water inlet filter regularly (every week) to prevent clogging by foreign objects such as insects, leaves, paper, hair, etc. and the air tightness of the water inlet pipe to prevent air from entering (air tightness in any link of the water inlet pipe section from the water tank to the pump body Not strict (no drip leakage occurs), gas will be inhaled under the self-priming negative pressure of the pump body), these two situations are the most likely scenarios to reduce the water jet pressure;

4. The filter must be checked before use in each shift to see if there are too many impurities and cleaned up;

5. The water tank must be checked regularly and kept clean. If there are impurities at the bottom, the sewage outlet should be opened to remove them;

6. When walking in a non-working state, the electric lifting device must be raised, and the switch must be turned to the "stop" state after raising to avoid collision;

7. Important: Turn off the power switch when the washing machine is not in use

8. It is strictly forbidden for the water tank to be short of water to avoid idling of the high-pressure pump.

13. Maintenance Instructions

1. The model used by the pump is 4-stroke motorcycle oil SAE15W/40.

2. After the new machine is used for 20 hours, the crankshaft of the pump must be cleaned. The specific method is as follows: remove the oil drain screw to drain the oil in the crankcase, re-install the oil drain screw, and then add clean kerosene to the crankshaft. After 10-15 seconds, turn off the equipment, drain the kerosene completely, and inject new oil.

3. After the accumulative use reaches 100 hours, change the oil in the same way, and then change the oil every 100 hours, which is very important to prolong the service life of the pump.

4. Winter maintenance:

(1) Use low temperature antifreeze oil (10W-30) when using in winter;

(2) Disconnect the water supply before entering the warehouse, run it for 2 seconds, and discharge the accumulated water in the pump (do not need to be exhausted) to prevent the water body from freezing, expanding, and damaging the pump body and plunger seals;

Note: Please carry out maintenance in strict accordance with the requirements. The manufacturer will not provide warranty for failures caused by untimely maintenance.

Home

Home About Us

About Us Product

Product After sales

After sales Contact Us

Contact Us